Core Objective & Fundamental Principle

Objective: To rapidly reduce the core temperature of food products through their critical ice crystal formation zone (typically 0°C to -5°C) to -18°C or below within minutes, minimizing ice crystal damage.

Principle: Utilizes the phase change (evaporation) of a refrigerant (e.g., Ammonia, R404A/R507, CO₂) within an evaporator coil. This absorbs heat, combined with high-velocity, ultra-low-temperature airflow, facilitating extremely rapid heat extraction from the product.

Key Distinction: Quick Freezing vs. Slow Freezing:

Slow Freezing (e.g., cold storage): Forms large ice crystals, rupturing cell walls. Results in: drip loss, texture degradation (tough meat, mushy vegetables), flavor/nutrient loss, poor appearance.

Quick Freezing: Forms numerous, uniformly distributed micro-crystals, preserving:

Moisture/juice retention

Natural color

Flavor compounds

Nutritional value

Texture & mouthfeel

Structural integrity

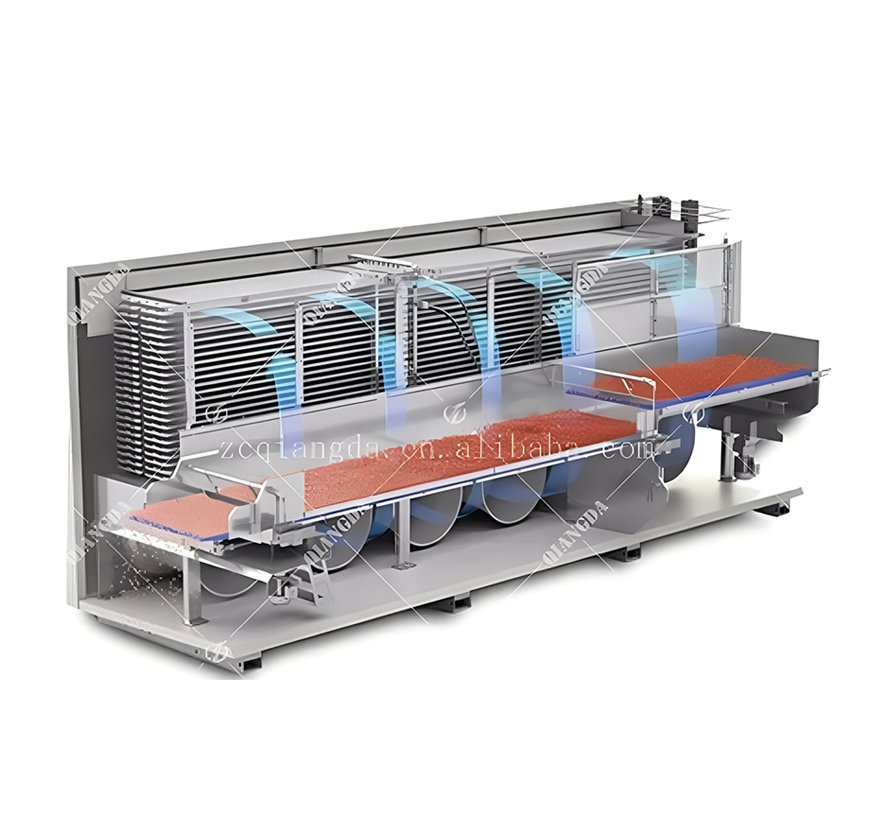

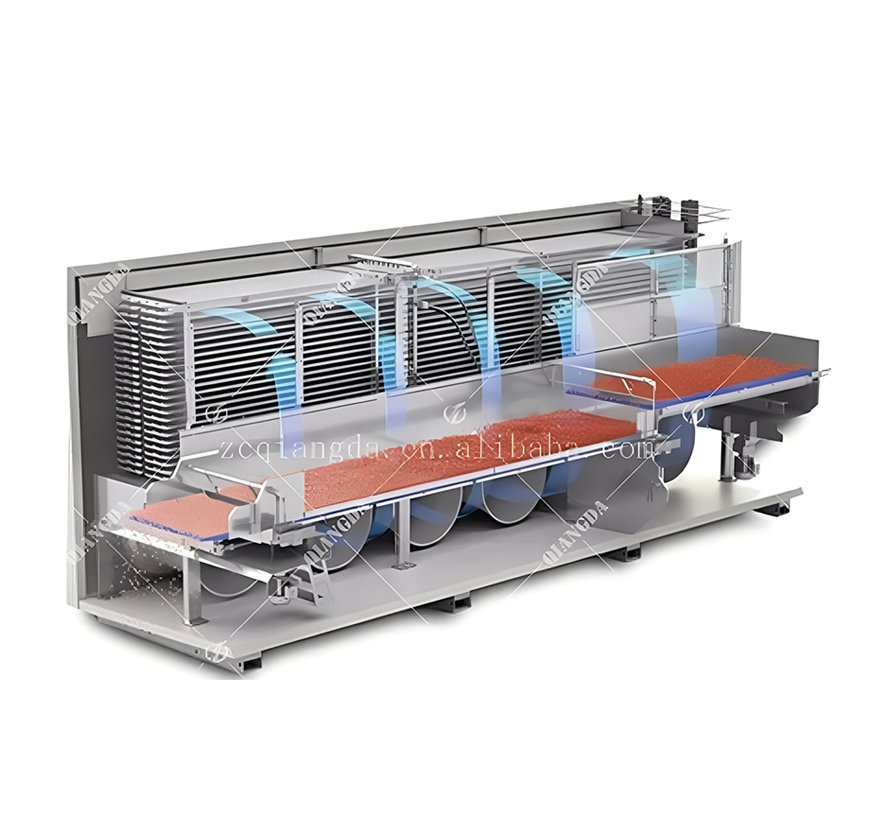

Working Principle & Process Flow (Forced-Air Tunnel Example)

Refrigeration Cycle Initiation:

The compressor starts, compressing the low-temperature, low-pressure gaseous refrigerant into a high-temperature, high-pressure gas.

The high-temperature, high-pressure gaseous refrigerant enters the condenser (either air-cooled or water-cooled), where it releases heat to the surrounding air or water, condensing into a high-pressure liquid.

The high-pressure liquid refrigerant passes through the expansion valve (or electronic expansion valve), throttling and reducing its pressure, turning it into a low-temperature, low-pressure liquid-vapor mixture.

The low-temperature, low-pressure liquid-vapor mixture enters the evaporator (located inside the freezer compartment).

Heat Transfer in Freezing Zone:

The low-temperature refrigerant inside the evaporator absorbs heat from the air flowing over it, evaporating (boiling) into a low-temperature, low-pressure gas.

A powerful fan (typically an axial or centrifugal fan) forcibly circulates a large volume of air within the freezer, blowing it at high speed over the cold evaporator fins, rapidly cooling the air to -30°C to -50°C or even lower (depending on the design).

This ultra-low-temperature, high-velocity airflow (typically 3-12 m/s or higher) is evenly blown toward or through the food being continuously fed on a conveyor belt.

The high-velocity airflow breaks down the stagnant air boundary layer around the food, greatly improving heat exchange efficiency.

The high-velocity cold air rapidly removes heat from the food surface, causing it to freeze rapidly.

The heat from within the food is continuously transferred to the surface, where it is then removed by the cold air, achieving rapid freezing from the outside in.

Product Freezing Stages:

Pre-cooling stage: Food cools from its inlet temperature (e.g., ambient or pre-cooled) to near freezing.

Maximum Ice Crystal Formation Zone: The food's core temperature passes through the 0°C to -5°C range. The key to quick-freeze machine design is expediting this stage to suppress the formation of large ice crystals.

Deep-freezing stage: The food's core temperature continues to drop to the target storage temperature (usually -18°C or lower).

Product Discharge & Air Recirculation:

Frozen product exits the tunnel.

Warmer air (after contacting product) is drawn back over the evaporator, re-chilled, and recirculated.

The Main Mechanical Components Of The Quick Freezer

Quick-freezing Tunnel/Chamber:

A well-insulated, enclosed space (typically constructed with polyurethane sandwich panels) where food freezing occurs. It has an inlet and outlet.

Conveyor System:

Types: Stainless steel mesh belt (most common), chain plate, spiral tower (space-saving), vibrating fluidized bed (suitable for small particles), hanging basket/push tray (suitable for large or irregular pieces).

Function: Carries food through the quick-freezing area at an adjustable speed, ensuring that each portion of food receives the same freezing time.

Evaporator (heat exchanger):

Composed of copper tubes/aluminum tubes with aluminum fins (or a plate heat exchanger).

The refrigerant evaporates within this chamber, absorbing heat and serving as the core component for cooling.

The design must ensure a large heat transfer area and good airflow.

Fan System:

Core component: High-efficiency, low-temperature-resistant axial or centrifugal fans.

Function: Provides strong, uniform airflow, efficiently transferring the cooling energy from the evaporator to the food surface. Airflow can be vertical (up and down), horizontal (co-current/counter-current), or a combination.

Refrigeration System:

Compressor: The "heart" of the system, providing power and compressing the refrigerant (piston, screw, scroll, etc., selected based on cooling capacity requirements).

Condenser: Dissipates heat to the ambient air, condensing the high-temperature, high-pressure refrigerant gas into liquid (air-cooled or water-cooled).

Expansion Valve: Controls the refrigerant flow rate, achieving throttling and pressure reduction (thermostatic expansion valve or more precise electronic expansion valve).

Refrigerant Piping and Accessories: Connects various components, including the liquid receiver, oil separator (large), filter, valve, control system sensors, etc.

Defrost System:

Frosting on the evaporator reduces efficiency. Common defrost methods:

Hot gas defrost: Utilizes high-temperature exhaust gas from the compressor directly into the evaporator to defrost (efficient and commonly used).

Water defrost: Defrosts by spraying warm water (requires drainage treatment and requires high hygiene requirements).

Electric Defrost: Defrosts using an electric heating element (high energy consumption, generally used for small equipment).

Our factory usually does water defrosting: defrosting is done by artificial warm water, and drainage pipes and stainless steel built-in floors are designed to facilitate hygienic cleaning.

Control System:

Core: PLC (Programmable Logic Controller) intelligent control.

Functions:

Set and monitor quick-freeze temperature, conveyor speed, and fan status.

Control refrigeration system start and stop, and adjust capacity.

Manage automatic defrost programs (time/pressure differential/temperature triggers).

Display operating parameters and alarm messages (temperature abnormalities, motor failure, excessive frost layer, etc.).

Record operating data (optional).

Insulation:

High-density polyurethane foam filler ensures cooling capacity is retained, reducing energy consumption.

Role in the Food Processing Line

The quick freezer is the critical preservation step, determining final frozen product quality:

Core Quality Preservation:

Locks in freshness, color, flavor, nutrients, texture, shape.

Microbial Control:

Rapid temperature drop inhibits pathogen/spoilage organism growth (HACCP critical control point potential).

Enzyme Inactivation:

Slows deteriorative reactions (browning, off-flavors).

Reduced Dehydration/Weight Loss:

Minimizes surface moisture sublimation ("freezer burn").

Enables Continuous Processing:

Integrates seamlessly with upstream (prep, cooking, coating) and downstream (packaging, inspection) operations.

Facilitates Downstream Handling:

Frozen product is rigid, easing packaging, weighing, metal detection.

Extends Shelf Life:

Enables long-term frozen storage, distribution, and retail.

Specification

| IQF - Individual Quick Freezing - tunnel freezer |

| 100kg | 200kg | 300kg | 500kg | 1000kg | 2000kg | 3000kg |

| Model | QSD-100 | QSD-200 | QSD-300 | QSD-500 | QSD-1000 | QSD-2000 | QSD-3000 |

| Structural type | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Freezing type | Blowing type | Blowing type | Blowing type | Blowing type | Blowing type | Blowing type | Blowing type |

| Air supply method | Top surface blowing type | Top surface blowing type | Top surface blowing type | Top surface blowing type | Top surface blowing type | Top surface blowing type | Top surface blowing type |

| dimensions mm | 7000*2500*1850 | 12000*2500*1850 | 15000*2800*2000 | 18000*2800*2100 | 21000*4000*2100 | 21000*7000*2200 | 30000*8000*2200 |

| Main storage unit length mm | 5500 | 10500 | 13500 | 16500 | 19500 | 19500 | 28500 |

| Mesh belt width (center to center distance) mm | 1300 | 1500 | 1500 | 1500 | 3000 | 3000*2 | 3000*2 |

| Packaging type | No packaging | No packaging | No packaging | No packaging | No packaging | No packaging | No packaging |

| Frozen product inlet temperature | ≤20℃ | ≤20℃ | ≤20℃ | ≤20℃ | ≤20℃ | ≤20℃ | ≤20℃ |

| Frozen product outlet temperature | ﹣18℃ | ﹣18℃ | ﹣18℃ | ﹣18℃ | ﹣18℃ | ﹣18℃ | ﹣18℃ |

| Freezing time | 20~60min | 20~60min | 20~60min | 20~60min | 20~60min | 20~60min | 20~60min |

| Freezing capacity | 100kg | 200kg | 300kg | 500kg | 1000kg | 2000kg | 3000kg |

| Inlet port length/height | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 |

| Outlet port length/height | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 | 900/600 |

| Number of storage doors | 1 | 1 | 2 | 2 | 3 | 4 | 6 |

| Storage unit thickness | 120mm | 120mm | 120mm | 120mm | 120mm | 120mm | 120mm |

| Polyurethane capacity of storage panels | ≥40kg/m³ | ≥40kg/m³ | ≥40kg/m³ | ≥40kg/m³ | ≥40kg/m³ | ≥40kg/m³ | ≥40kg/m³ |

| Mesh belt speed | 连续可调 | 连续可调 | 连续可调 | 连续可调 | 连续可调 | 连续可调 | 连续可调 |

| Storage freezing temperature | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ | ﹣45℃~﹣35℃ |

| Installed power | 3kw | 5.15kw | 13kw | 18kw | 28.5kw | 54kw | 82kw |

| Cooling source power | 22kw | 44kw | 66kw | 56.25kw | 112.5kw | 225kw | 337.5kw |

| Refrigeration medium | R22 | R22 | R22 | R22 | R22 | R22 | R22 |

| Cooling source configuration | Dual 30HP pistons | Dual 30HP*2 pistons | Dual 50HP*3 pistons | Dual 75HP screws | 150HP twin screws | 150HP twin screws*2 | 150HP twin screws*3 |