Main Classifications & Their Key Differences

Drying rooms are primarily categorized by their heating technology, which dictates their efficiency, cost, and suitability for different products.

Type / Feature

•Heat Pump Drying Room

•Electric Drying Room

•Steam Drying Room

How It Works

The Drying Process The operation can be broken down into a continuous cycle:

•Air Heating: The chosen heat source (heat pump, electric element, burner) raises the temperature of the air.

•Moisture Absorption & Evaporation: The hot, dry air is circulated by powerful fans over the product, causing surface moisture to evaporate.

•Humidity Exhaust: The now moist, cooler air passes through the system. In open-loop systems, a portion of this humid air is vented out and replaced with fresh air. In closed-loop systems (common in heat pumps), it passes through a dehumidifier where moisture is condensed and removed, and the dry air is reheated and reused.

•Recirculation/Reheating: The dried air (in a closed loop) or fresh air (in an open loop) is reheated and the cycle repeats until the target moisture content is achieved.

Key Advantages & Benefits

•Controlled & Uniform Drying: Prevents over-drying or under-drying, ensuring consistent batch quality.

•High Efficiency & Throughput: Significantly faster and more efficient than traditional sun-drying or simple oven-drying.

•Superior Product Quality: Preserves color, flavor, aroma, and nutritional content better than uncontrolled methods.

•Hygiene & Food Safety: Enclosed system protects products from dust, insects, and contaminants.

•Weather & Season Independence: Allows for continuous, year-round production.

•Reduced Labor Costs: Automated systems require minimal supervision.

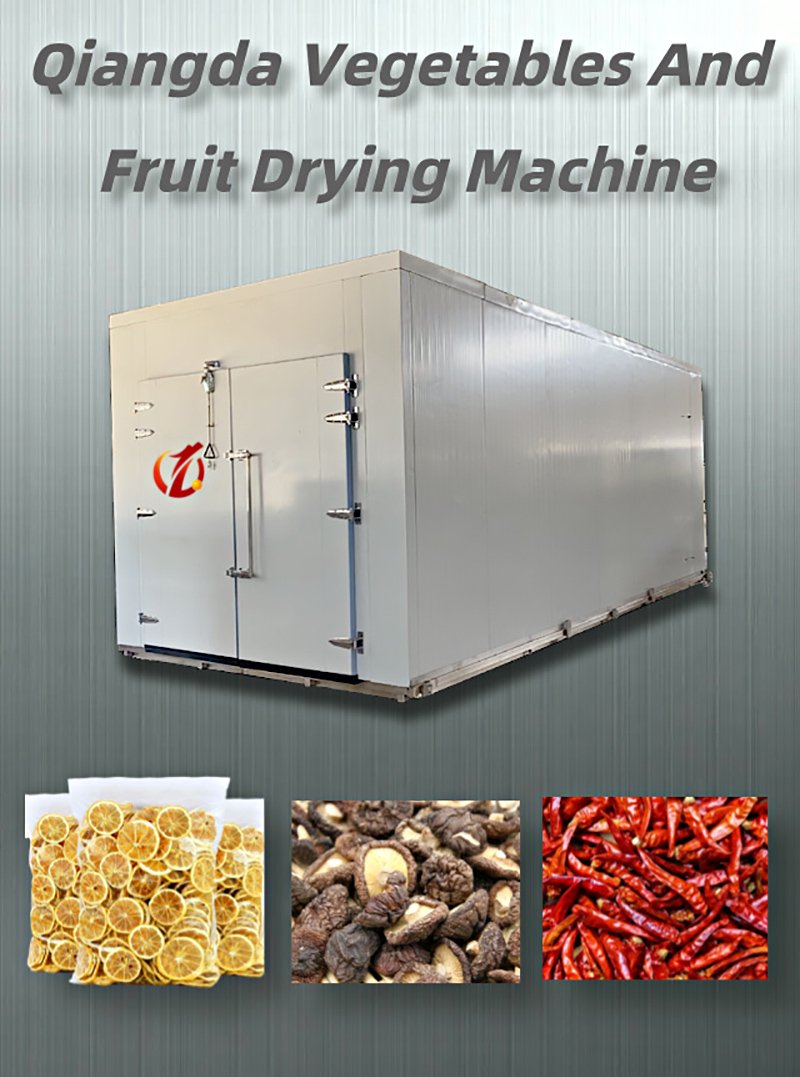

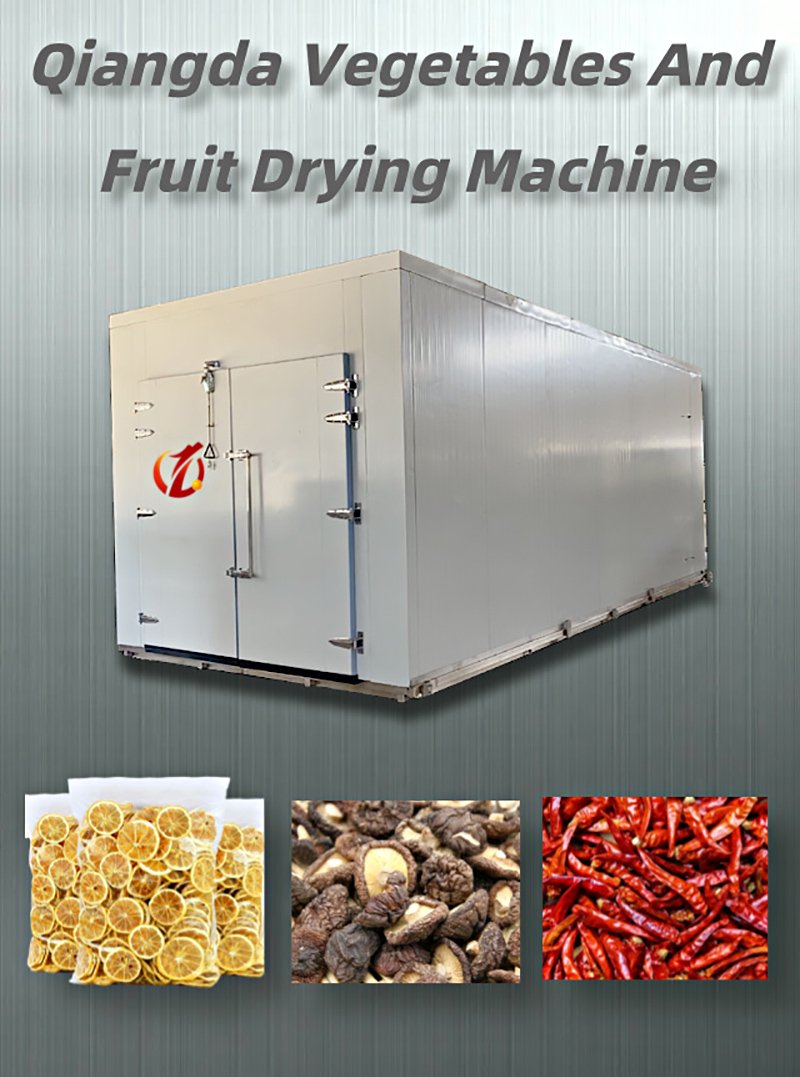

Common Applications

•Food Processing:

Seafood: Drying squid, fish, shrimp, scallops.

Fruits & Vegetables: Making dried mango, bananas, mushrooms, onions.

Meat Products: Curing and drying sausages, ham, beef jerky.

•Agricultural & Herbal Products: Drying herbs, tea leaves, medicinal plants (ginseng, cannabis), grains, and nuts.

•Industrial Manufacturing: Drying lumber, textiles, paper, ceramics, and certain chemicals.

Product Details Display

Heat pump unit

Axial-flow fan

Vortex fan

Control system

Drying room board

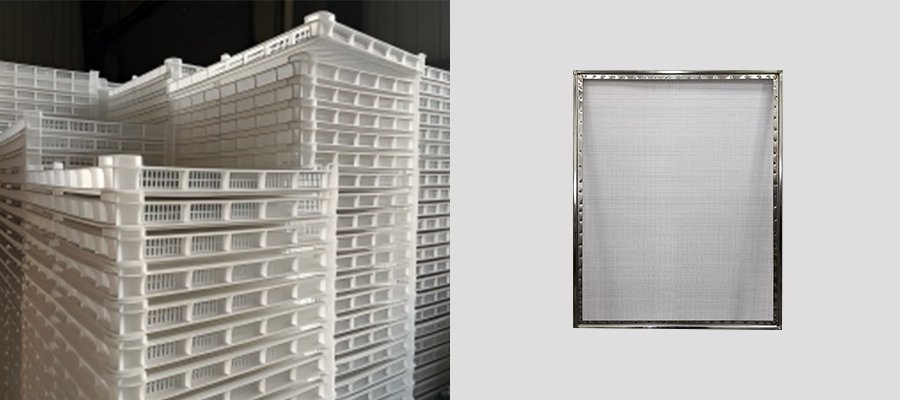

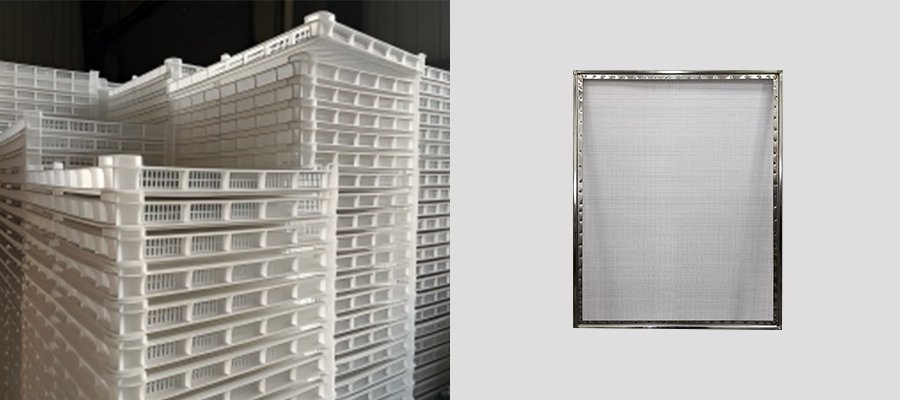

Trolley

Tray

Specification

Heating method | Heat pump | Electric ≤600℃ | Steam 50~150℃ |

Low temperature ≤45℃ | High temperature ≤75℃ |

Working principal | Extracts ambient heat from the air; compresses it to create high-temperature, dry air. A reverse refrigeration cycle | Uses electric heating elements to heat air directly | Uses steam from a boiler, circulated through pipes/finned coils, to heat the air. |

Advantage | Higher Initial Investment. Efficiency can drop in very cold environments. | Simple & Low Initial Cost. Clean and easy to install. | Stable & Safe heat. Cost-effective if steam is already available. |

Ideal For | High-value, heat-sensitive products: Seafood, premium herbs, pharmaceuticals, fruits. | Small batches, R&D, areas with cheap electricity. | Large factories with existing steam infrastructure. |

Models | 3P | 5P | 7P | 15P | 25P | Depends on capacity | Depends on capacity |

Fans | Centrifugal Fan | High-Temperature and High-Humidity Axial Flow Fan |

Drying room board | 100mm polyurethane |

Drying room dimension | Depends,customized |

Trolley | 1200*800*1800mm,SUS201. customized |

Tray | 800*600mm,PE,SUS304.customized |