Product Details Display

The equipment is divided into multiple independent temperature zones, including preheating, sterilization, and cooling. Each zone is equipped with an independent intelligent temperature control system and heating/cooling unit to precisely set and maintain the desired temperature. This stepped temperature change effectively kills microorganisms while preventing sudden temperature changes that could cause glass bottles to burst or packaging to deform.

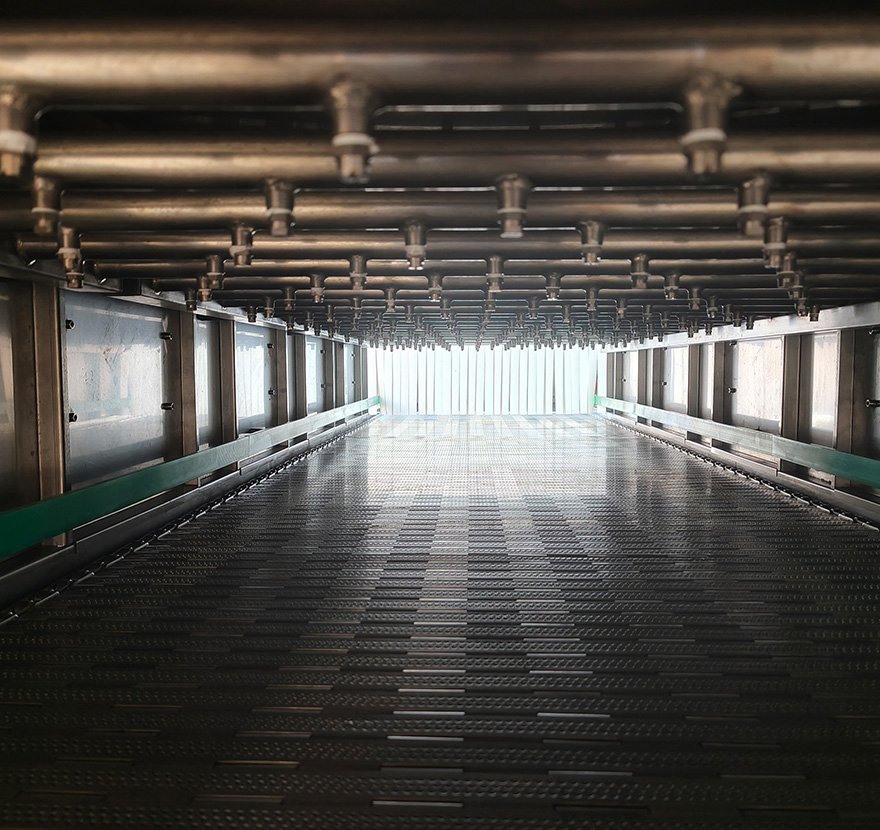

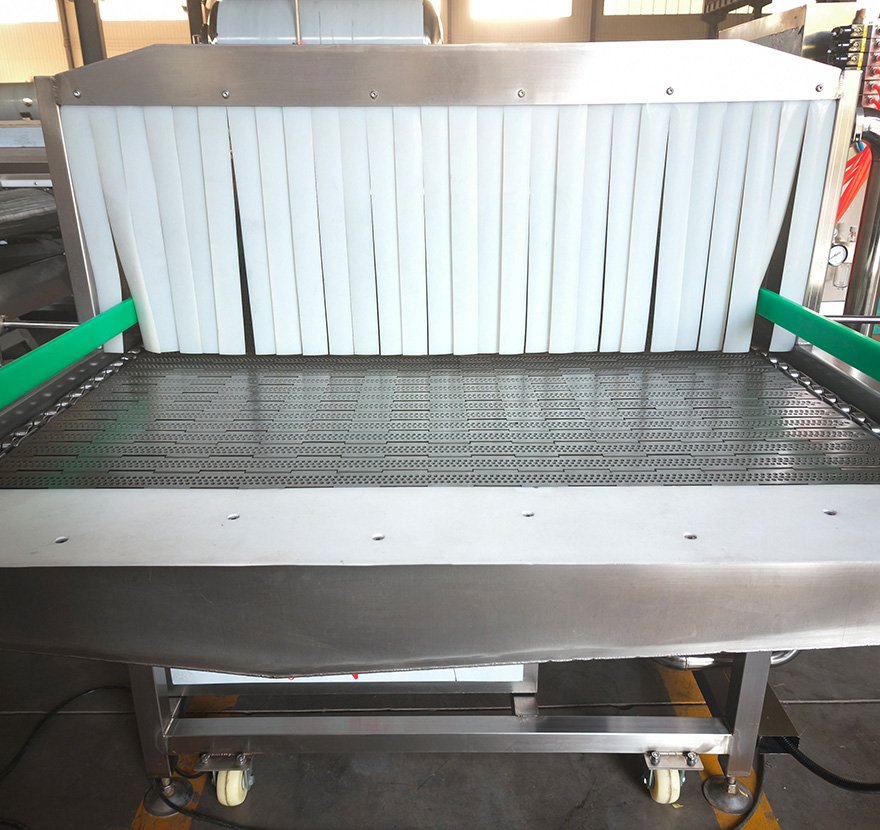

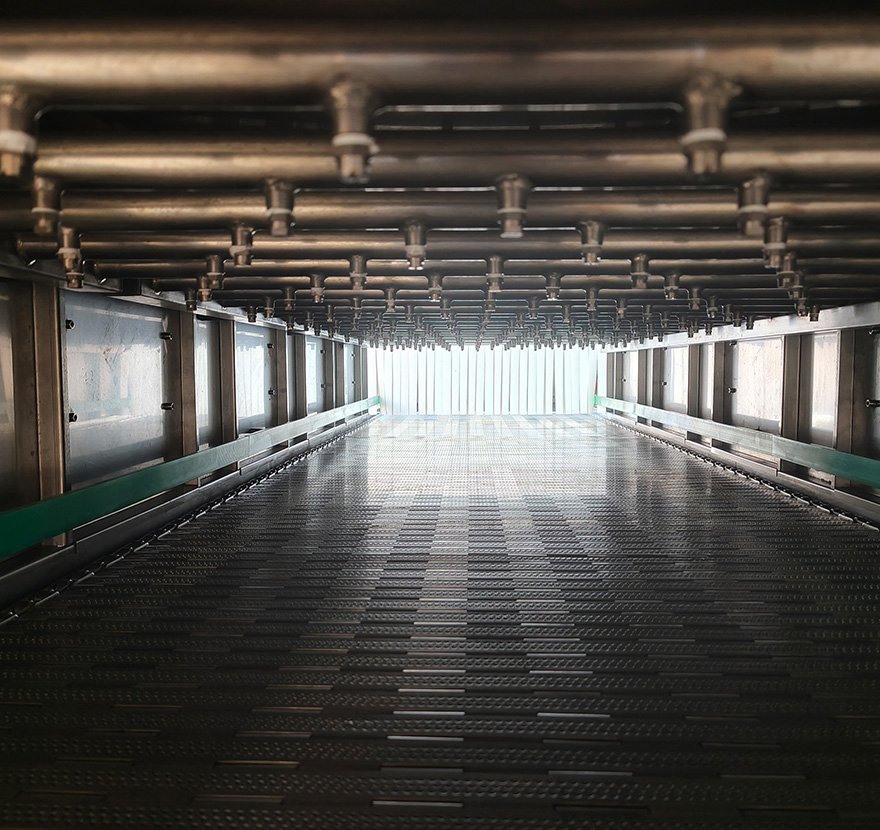

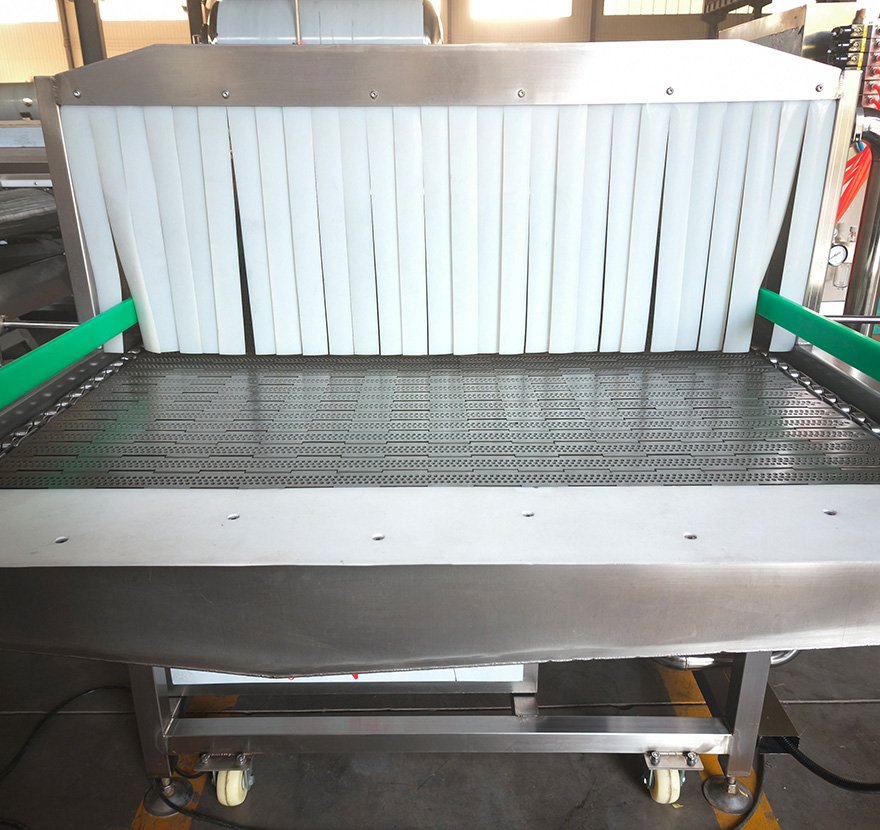

This is the core of our equipment. It utilizes a circulating spray system. The spray head, optimized through fluid dynamics, ensures that water droplets evenly and densely cover every corner of the bottle/can, eliminating any sterilization blind spots. This design ensures a thorough exchange of heat energy with the product, resulting in sterilization efficiency far exceeding that of conventional immersion systems.

The conveyor belt is constructed of high-strength stainless steel, ensuring smooth operation and a strong load-bearing capacity. The drive system utilizes variable frequency drive, allowing for flexible and precise control of the sterilization time (typically adjustable to tens of minutes) based on product type and process requirements. Guardrails are installed on both sides of the belt to ensure stable and orderly product transport

The entire box adopts a fully enclosed structure. This design can prevent heat loss to the greatest extent, not only creating a stable internal thermal environment and ensuring the uniformity of the sterilization effect, but also effectively reducing the temperature of the equipment surface, improving the workshop working environment, and saving energy and protecting the environment.

Equipped with a large color touchscreen as the control center, the integrated PLC system provides clear operation. You can easily set and store multiple sets of process parameters and monitor key data such as temperature in each zone and belt speed in real time. The system supports self-diagnosis of faults and generates sterilization process curves, providing data support for product quality traceability.

Specification

| Model | Installed power | Mesh belt width | Size | Heating method |

| QD-2200 | 26kw | 2200mm | 9800*2400*1700mm | Steam heating |

| Spray type sterilization cooling machine: |

| OVERALL DIMENSIONS | 9800X2400X1700mm |

| NETWORK BELT CENTER DISTANCE | 2200mm |

| INSTALLED POWER | 26KW |

| HEATING MODE | Steam heating |

Note:the size of the equipment can be customized

according to customer requirements. |