Core Operating Principle: Smooth and Uniform Three-Dimensional Freezing

The operating principle of the spiral freezer can be summarized as "three-dimensional conveying, uniform freezing." The process is as follows:

Feeding and Elevating: Products are fed into the machine from the feed port via a horizontal mesh conveyor belt, where they are smoothly transferred to the elevating mesh belt within the spiral tower.

Spiral Ascent/Descend: Driven by a powerful variable frequency drive system, products move upward (or downward) along the spiral tower at a uniform and stable speed. During this process, products are prevented from stacking, tipping over, or falling, ensuring their visual integrity.

Uniform Forced Cooling: Within the spiral tower, efficient, uniform vertically circulated cold air is blown from above or the sides, tightly enveloping and penetrating the product layers. The cold air temperature typically reaches -35°C to -40°C, and the high-velocity airflow rapidly removes heat from the product, achieving rapid freezing.

Discharging and Finishing: After completing the preset number of spiral turns and reaching the center freezing time, the product is conveyed to the discharge port, completing the freezing process and delivering a consistent quality quick-frozen product.

Key Features: The unique "building block" structure allows for flexible adjustment of freezing time (typically ranging from 10 minutes to several hours) by increasing or decreasing the number of spiral turns, perfectly adapting to a variety of product sizes, from thin fish fillets to thick cuts of meat.

Equipment Materials and Structure: Crafted with Craftsmanship, Durable

Our meticulous attention to materials and structure fundamentally ensures the equipment's long-term stable operation and compliance with food hygiene and safety standards.

Component Type Material and Features Benefits

Conveyor Belt: Utilizes high-strength SUS304 stainless steel mesh belts or food-grade plastic chain plates, offering a smooth surface and low friction. These belts meet food hygiene standards, are corrosion-resistant, resist product sticking, and are easy to clean.

Spiral Tower Structure: The central drum is constructed of high-strength stainless steel, while the support rods and guide rails are also constructed of high-quality stainless steel, ensuring a stable overall structure. This ensures smooth operation, effectively prevents conveyor belt deviation, and offers a long service life.

Insulated Storage: Utilizes polyurethane insulation panels (double-sided stainless steel or color-coated steel) with a thickness of at least 100mm, offering low thermal conductivity and excellent sealing. This superior insulation performance effectively reduces energy consumption and prevents cold bridging.

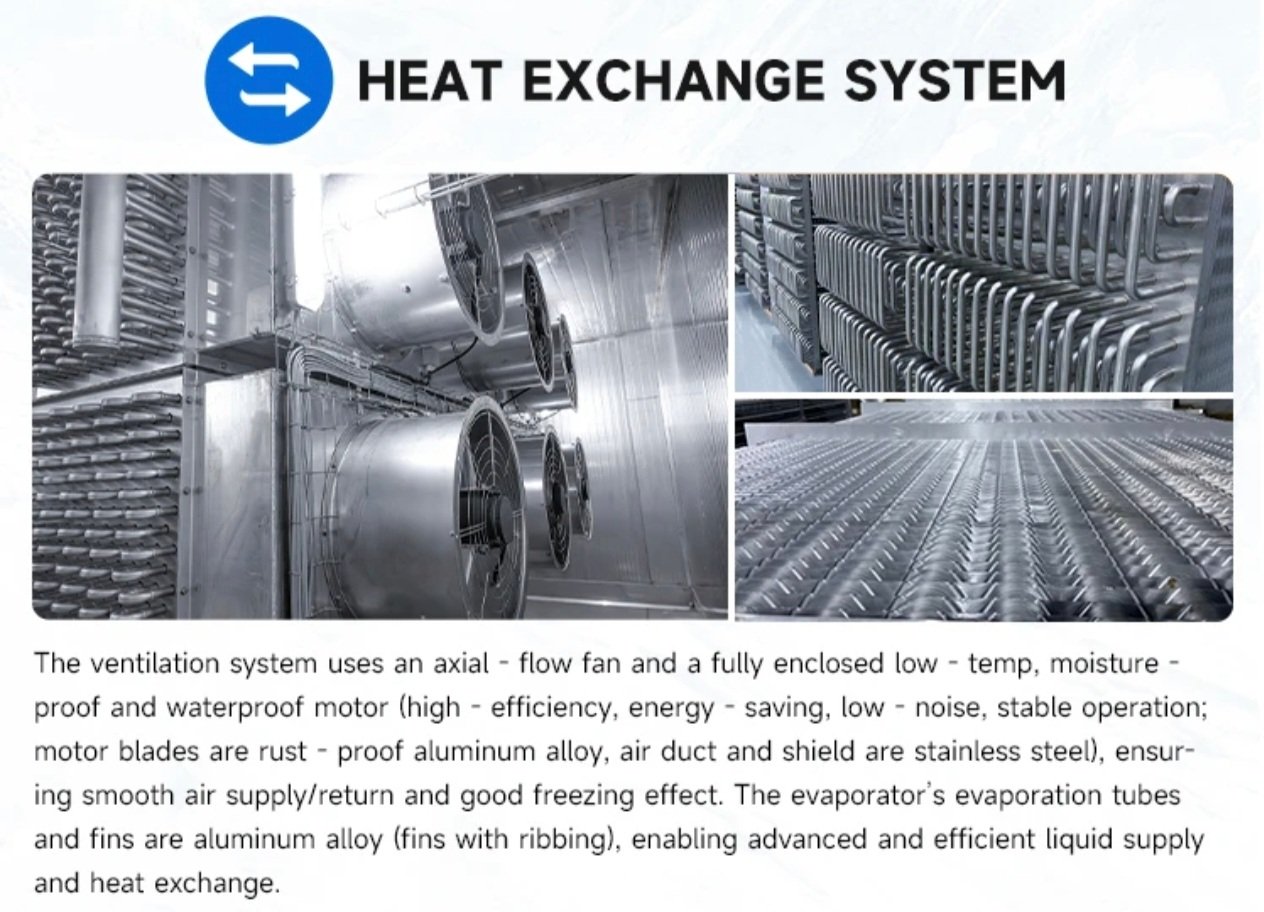

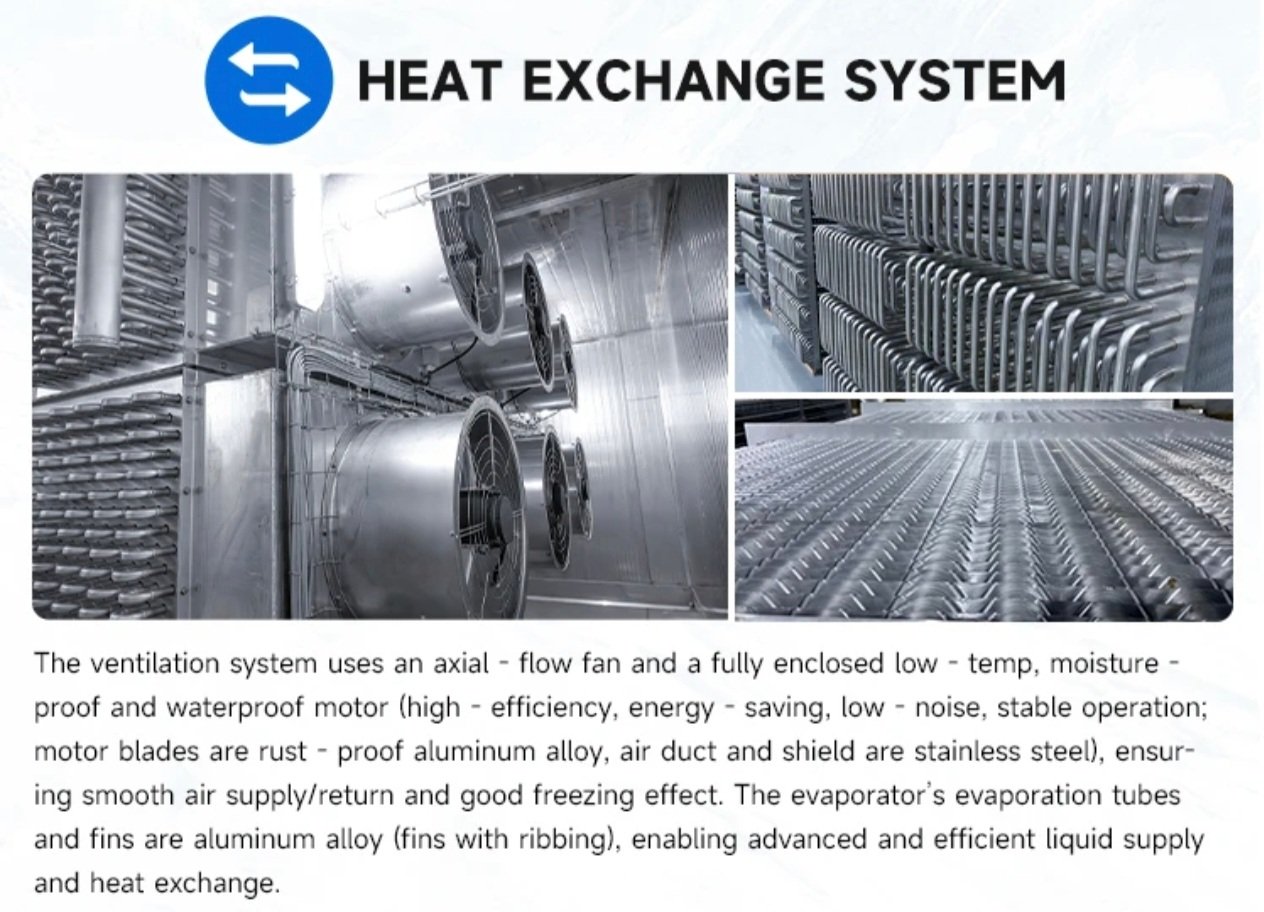

Evaporator: The all-aluminum alloy fin evaporator features a variable fin pitch design, slowing frosting and extending effective operating time. High heat exchange efficiency reduces defrosting times, ensuring continuous production. The drive system utilizes a central drum drive or friction wheel drive, equipped with a variable frequency motor for precise control. It operates smoothly and quietly, with infinitely adjustable speed to accommodate different products.

Highlights: Why Choose Our Spiral Freezer?

Optimum Space Utilization: The revolutionary three-dimensional design achieves an extra-long freezing line in a very small footprint, with a freezing capacity per unit area several times greater than tunnel-type freezers, saving you valuable production space.

Excellent Product Integrity: The smooth spiral conveying process avoids violent collisions and squeezing between products, perfectly preserving the original shape of fragile products (such as fried foods and strawberries), and achieving a high yield rate.

Efficient and Energy-Saving Operation:

Optimized airflow distribution: Ensures even cold distribution, eliminating freezing spots.

High-performance insulated storage panels: Minimizes cold loss.

Flexible Defrosting Control: Intelligently schedules defrost based on production schedules and frost conditions, improving energy efficiency.

Flexibility and Adaptability: The freezing time can be infinitely adjusted within a wide range, allowing one machine to be used for multiple purposes, meeting the production needs of a wide variety of products and specifications, helping you flexibly adjust your product line.

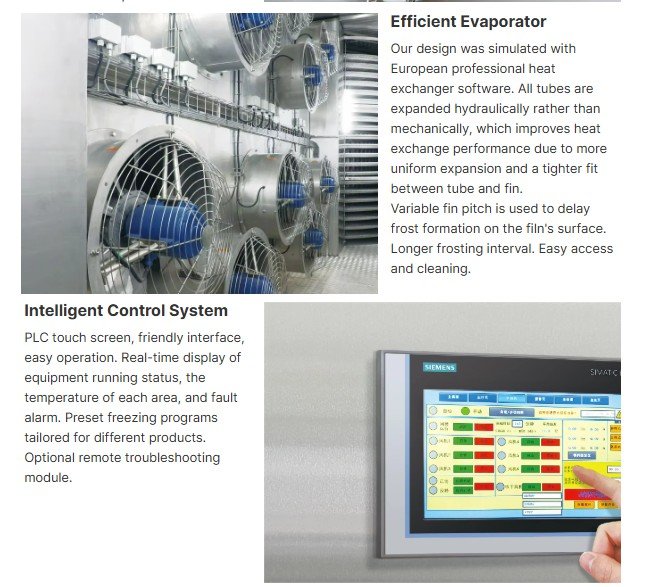

Highly Automated and Intelligent: The PLC + touchscreen control system enables one-touch start and stop, fault self-diagnosis, operating parameter recording, and remote monitoring, significantly reducing operation difficulty and labor costs.

Wide Range of Applicable Product Types

Spiral freezers are particularly suitable for individually frozen (IQF) products, products with irregular shapes, or products requiring longer freezing times:

Breaded and fried products: Chicken nuggets, popcorn chicken, fried shrimp, fish fillets, etc. (perfectly retaining the crispy crust).

Seafood: Shrimp, scallops, fish fillets, fish chunks, and various high-value whole fish.

Meat and poultry: Chicken nuggets, steaks, meatballs, roasts, and various poultry cuts.

Prepared meals and prepared foods: Boxed meals, curries, soups, and various ready-to-eat meals.

Fruits and vegetables: Delicate and fragile fruits and vegetables such as strawberries, blueberries, asparagus, and corn.

Pasta and other pastries: Dumplings, spring rolls, glutinous rice balls, steamed buns, and various dim sum.

Specification

| IQF MATCH TABLE |

Quick-freezing tunnel/quick-

freezing machine

(temperature-35℃) | Frequency conversion

(30~80HZ) | Power

distribution

reference | Fixed frequency | Power distribution

reference |

| Productivity/type | Capacity

request

(KW) | Hanbell

compressor | Capacity

(KW)

(5000r/min=80

HZ) | Power

distribution

(kW) | Hanbell

compressor | Capacity(kw) | Power distribution

(kW) |

500kg/h

Tunnel freezerlspiral

quick freezer | 100 | LT-8-3012-V | 113 | 126 | LT-S-4520 | 105.1(50hz) | 82 |

| 119.85(60hz) |

750kg/h

Tunnel freezerispiral

quick freezer | 140 | LT-S-4520-V | 158 | 161 | LT-S-6532 | 154.7(50hz) | 122.2 |

| 175.93(60hz) |

1 ton/h

Tunnel freezer /spiral

quick freezer/fuidized | 180 | LT-S-5525-V | 187 | 180 | LT-S-8341 | 195.2(50hz) | 145.2 |

| 218.16(60hz) |

1.5 ton/h

Tunnel freezer/spiral

qulck freezerfuidized | 240 | LT-S-8341-V | 256 | 269 | LT-S-5525 | 268.4(50hz) | 198.7 |

| 269.5(60hz) |

2 ton/h

Tunnel freezer /spiral

quick freezer/fuidized

freezer | 310 | LT-S-4520-V | 316 | 327 | LT-S-6532 | 309.4(50hz) | 245.2 |

| 351.86 (60hz) |

2.5 tonh

Tunnel freezer/spiral

quick freezerfuidized

freezer | 400 | LT-8-4520-V | 474 | 482 | LT-8-8341 | 390.4(50hz) | 290.9 |

| LT-S-6532-V | 430 | 457 |

| 436.32(60hz) |

3 ton/h

spiral quick

freezer/fluidized | 460 | LT-8-8341-V | 576 | 538 | LT-8-6532 | 464.1(50hz) | 363.9 |

| 527.79(60hz) |

4 ton/h

spiral quick

freezer/fluidized

freezer | 580 | LT-8-5525-V | 748 | 731 | LT-S-8341 | 585.6(50hz) | 442.4 |

| LT-S-6532-V | 645 | 694 | 654.48(60hz) |

5 tonh

spiral quick

freezer/luldized | 690 | LT-S-8341-V | 768 | 807 | LT-S-8341 | 780.8(50hz) | 593.8 |

| 872.64(60hz) |